This Car Parts Mold product is perfect for quality automotive

parts, custom car parts, and automotive parts manufacturing.

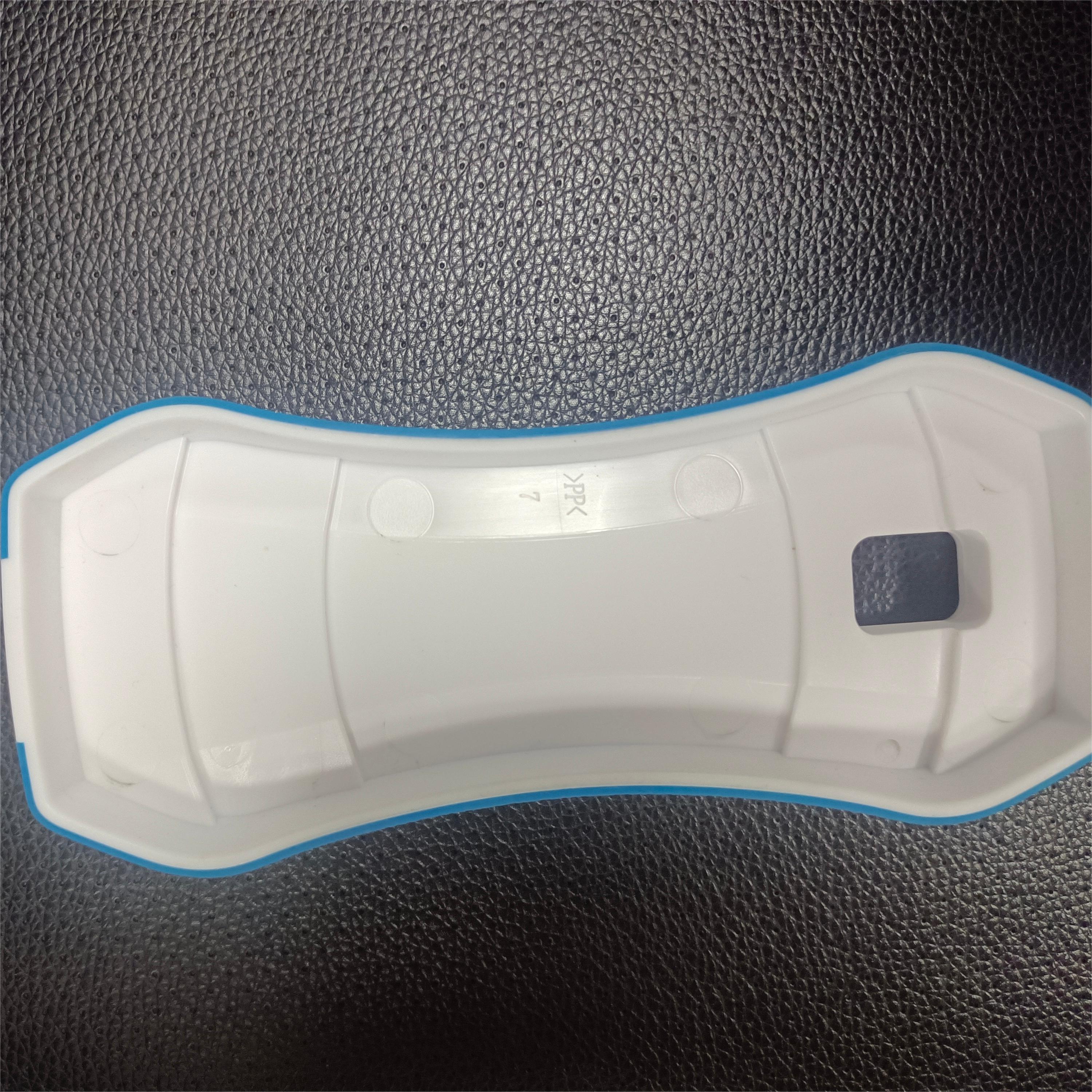

In modern industrial design, colour is not only a kind of visual

enjoyment, but also an important part of brand identification and

product function. The injection art of blue and white two-colour

lid mould is a vivid embodiment of this concept. It not only

combines colour aesthetics with practical functions, but also

achieves the perfect unity of design and manufacturing through the

precision injection moulding process. This article will explore

this area in depth, revealing the design concept, process and

technological innovation behind the blue and white two-colour lid

mould.

Design concept: dialogue between colour and function

The design of the blue and white two-colour lid is inspired by both

nature and human culture. Blue represents freshness and

technological sense, while white signifies purity and simplicity.

When these two colours meet on the lid, they are not only visual

embellishments, but also convey product information in silence. The

blue and white lid not only increases the recognition of the

product, but also guides the user to use it correctly in an

invisible way, such as distinguishing containers for different

purposes and suggesting the direction of opening, etc., which shows

the unique role of colours in the expression of functions.

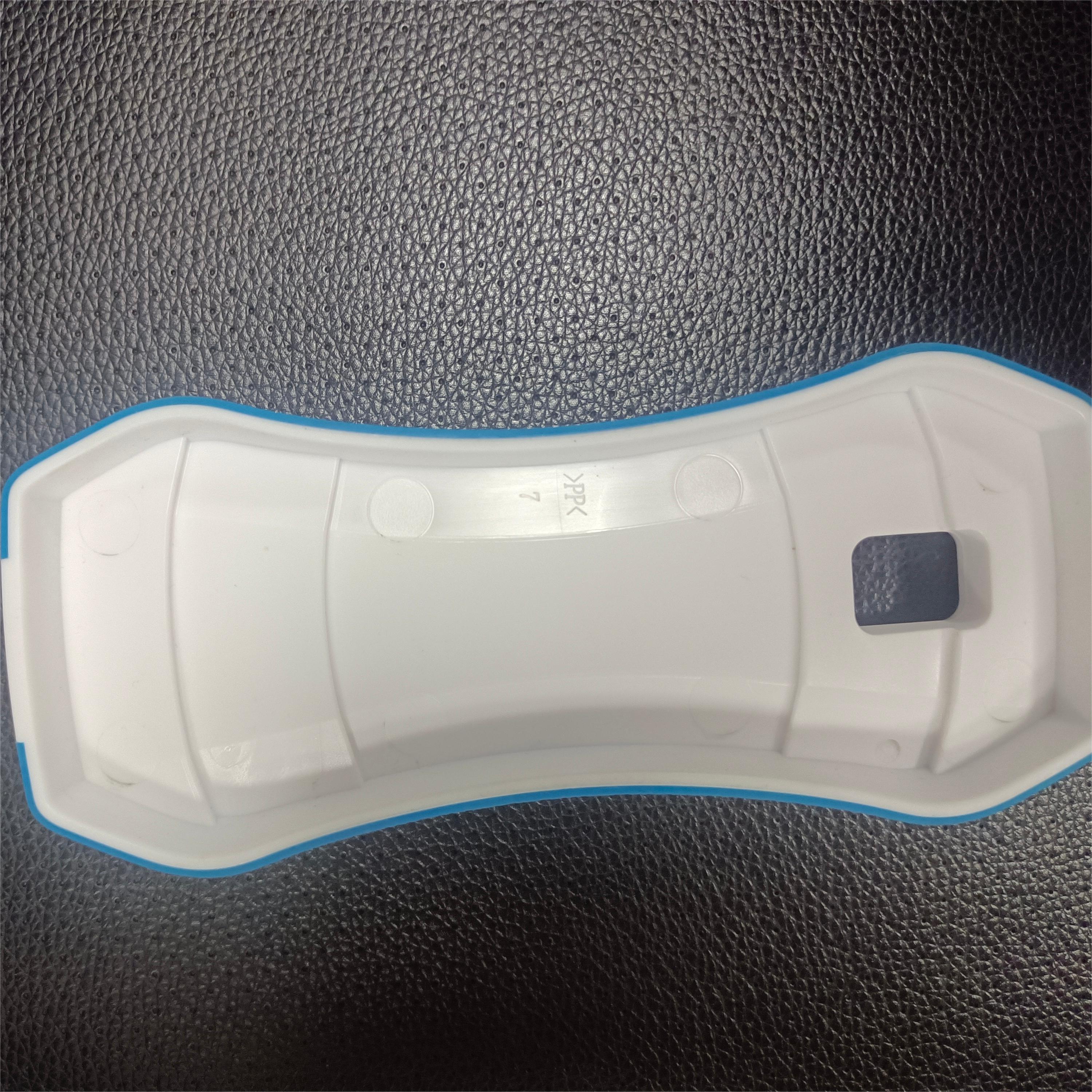

Process: the subtleties of two-colour injection moulding

The two-colour injection moulding technology is the key to

realising the design of the blue and white two-colour lid mould.

This process requires the injection moulding of two different

coloured materials in a single mould, without the need for

secondary assembly. The core difficulty lies in ensuring that the

two materials are accurately aligned during the injection moulding

process, creating a seamless appearance, while ensuring the

structural strength and sealing performance of the lid. This

requires a high level of skill on the part of the mould designer,

and every step, from the innovation of the mould structure to the

precise control of the injection parameters, needs to be carefully

considered.

Technical innovation: pursuing higher standards

As consumers' pursuit of product personalisation and high quality

continues to rise, the injection moulding process of blue and white

two-colour lid moulds is also constantly innovating. The

application of new materials, intelligent production process

control, and more environmentally friendly manufacturing methods

are all driving technological progress in this field. For example,

the use of bio-based plastics as raw materials not only enables the

accurate rendering of colours, but also reduces the environmental

impact; the integration of intelligent sensors and data analysis

systems makes the production process more transparent and

controllable, and improves the stability and consistency of the

finished product.

Conclusion: The perfect balance of art and function

The injection art of the blue and white dual-colour lid mould is a

perfect blend of colour and function, aesthetics and technology. It

not only enhances the visual appeal of the product, but also

enhances the user experience. With the continuous evolution of

design thinking and the innovation of manufacturing technology, we

can expect more dual-colour lid products with both aesthetics and

practicality to emerge, adding a splash of colour to daily life and

bringing new insights to the field of industrial design. In the

interweaving of colour and function, the blue and white two-tone

lid mould is writing a new chapter of industrial design with its

unique injection art.