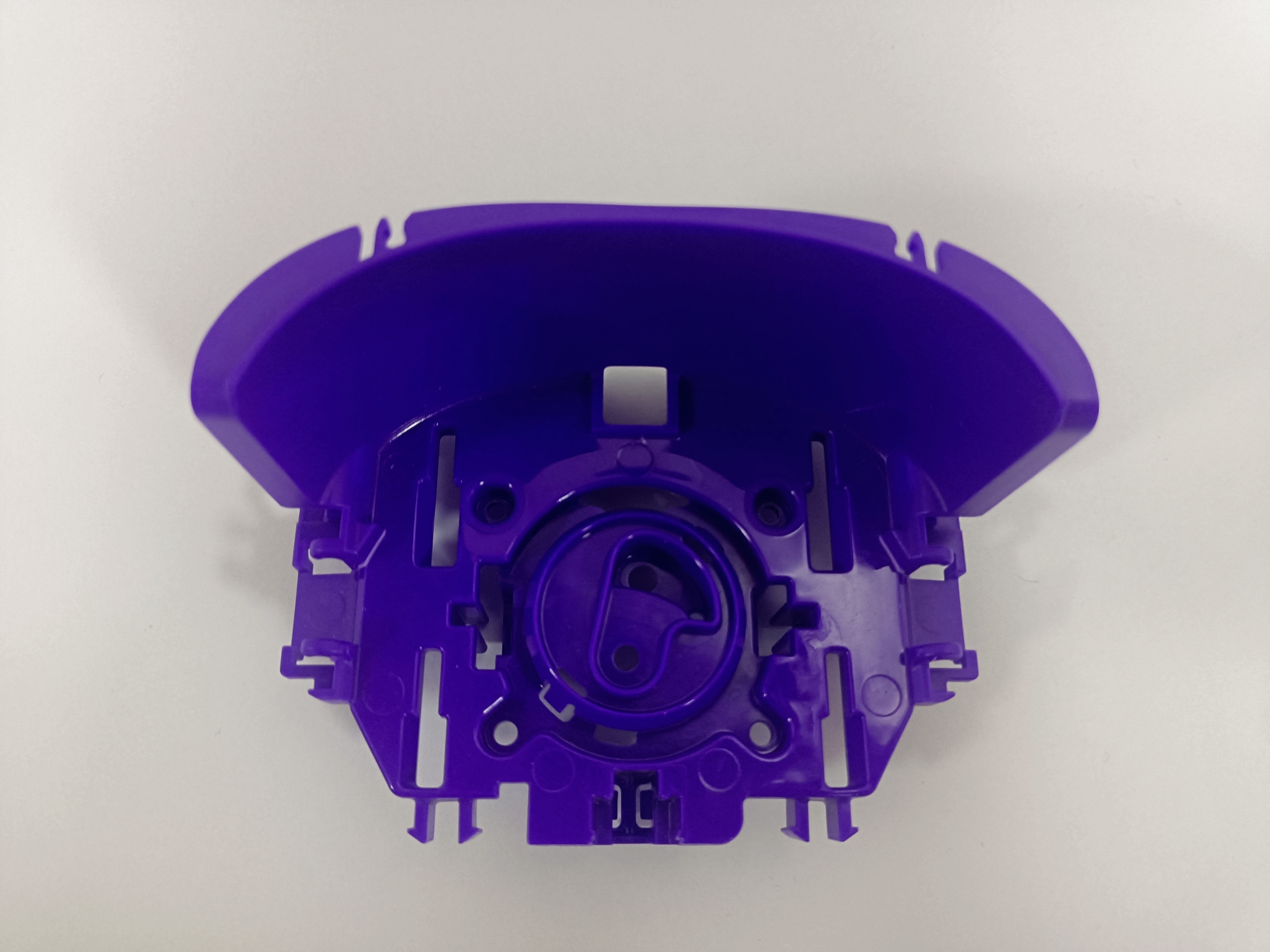

This Car Parts Mold product is perfect for quality automotive

parts, custom car parts, and automotive parts manufacturing.

In today's industrial manufacturing world, colour is more than just

an aesthetic pursuit; it is a brand identity and a reflection of

product functionality. For manufacturers seeking to incorporate

specific colours into their designs, bespoke coloured moulds are

becoming a trend, especially in the production of plastic parts

that require high precision and consistency. This article will

focus on the specialist production process of custom purple gear

moulds, exploring how the fusion of technology and craftsmanship

can achieve the perfect combination of quality and colour.

I. The importance of colour

In many industries, colour is a key factor in differentiating

different product lines or enhancing brand image. For example, in

the automotive, electronics and toy industries, specific colours

can inspire consumers to buy or communicate certain features and

functions of a product. For critical mechanical components such as

gears, the use of purple not only enhances product recognition, but

may also be indicative, such as distinguishing between different

sets of gears or for quick identification during maintenance and

assembly.

Production process of customised purple gear moulds

1. Design and Planning

First of all, the designer carries out a detailed design of the

mould according to the customer's needs, including the size and

shape of the gears as well as the colour requirements. This step

requires precise calculations and simulations to ensure that the

mould can be accurately shaped during the injection moulding

process.

2. Material selection

Choosing the right material is crucial to ensure the durability of

the mould and the quality of the final product. For purple gear

moulds, in addition to considering the mechanical properties of the

material, it is also necessary to ensure that it can withstand

treatment with dye without compromising strength or stability.

3. Colouring technology

The dye is added directly to the plastic raw material to ensure

that the colour is evenly distributed throughout the gear. This

requires precise proportioning and mixing techniques to achieve the

required depth and consistency of purple colour.

4. Mould Manufacturing

Every detail of the mould is precision manufactured using advanced

CNC machining centres and EDM forming technology. This process

requires extreme precision to ensure that the gear teeth are

accurately shaped while maintaining colour uniformity.

5. Testing and Adjustment

After completing the mould, a series of tests will be carried out,

including trial moulds and product quality checks. If any problems

are found, such as uneven colours or dimensional deviations, the

mould will need to be fine-tuned until all criteria are met.

III. Quality Control and Colour Management

In order to ensure the high quality of the final product, the whole

production process needs to strictly follow international quality

management system standards such as ISO9001. In addition, colour

management is also a key aspect. Professional colour analysis

instruments are used to detect and calibrate the colours to ensure

that each batch of products meets the purple standard expected by

customers.

Conclusion

Custom purple gear mould is not only a technical challenge, but

also a perfect combination of art and science. Through precise

design, material selection, dyeing techniques and strict quality

control, manufacturers are able to bring to market coloured gear

products that are both aesthetically pleasing and functional,

meeting the demands of modern industry for individuality and

quality. In the future, as technology continues to advance, we have

reason to believe that custom coloured moulds will become an

important tool for innovative design in more industries.