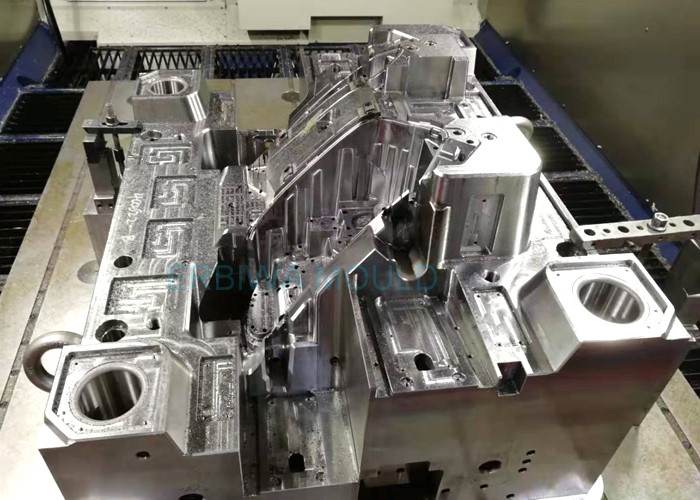

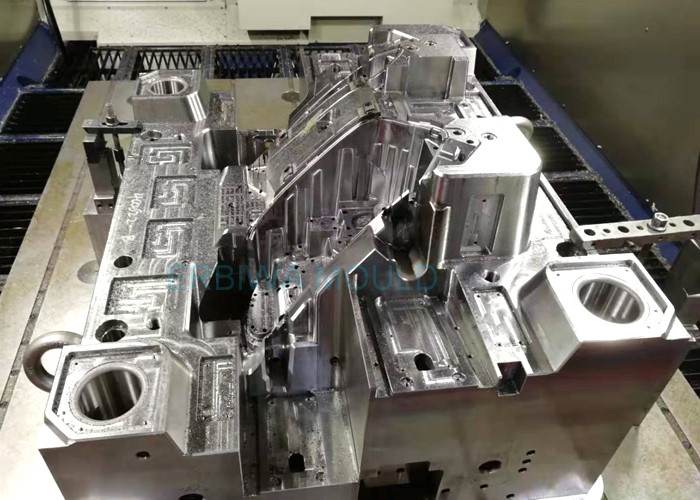

Injection Parts Mold Made For Automotive Housing Part / Auto

Lighting System

• Key Specifications/Special Features:

| Company | ERBIWA MOULD INDUSTRIAL Co., Ltd |

| Business Type | Manufacturing |

| Products Name | Chinese high quality customized plastic injection molding for Car

Plastic Secondary Instrument Panel/Dashboard |

| Place of Origin | Dongguan, China |

| Export Country | Germany, Japan, North America, Australian, Canada, France, Italy,

etc |

| Quality System | ISO9001: 2015; IATF16949: 2016 |

| Mould Life | 300K-1000K Shots |

| Mould base Standard | HASCO, DME, LKM, Meusburger, FUTABA, etc |

| Core & Cavity Material | 718H, P20, NAK80, S316H, SKD61, 1.2311, 1.2343, 1.2343ESV, etc |

| Products Material | PP, PA6, PLA, ABS, PE, PC, POM, PVC, PET, PS, TPE/TPR, etc |

| Design Software | UG, PROE, Auto CAD, Solidworks, Catia V5, Visi, etc |

| Runner Type | Hot runner or cold runner |

| Gate Type | Side gate, Sub gate, Pin point Gate... |

| Surface Treatment | Polish, High gloss Polish, Texture, Silk-screen printing, Brushed,

Mirror, Anodizing, Electroplating, etc |

| Equipment | CNC, EDM, Milling, Grinding, Wire Cut, Inspection, Plastic

injection machine |

| Package | Wooden box for mould, carton for plastic products |

| Lead Time | 30-40 days for T1 |

| OEM/ODM Service | Available |

• Plastic mold production process

Plastic Mould Production Process

| Description |

| 1 | 2D/3Ddesign or samples for inquiry | Offer quotation according to customer's drawing or samples |

| 2 | Discussion/Negotiation | Including the price of moulds, moulds sizes, material for cores &

cavities, payment terms , mould lifetime, delivery, etc. |

| 3 | Purchasing Order | After the customer confirming the mould design and quotation |

| 4 | Mould Making | Confirm drawing, start to do DFM, mold flows and mold details |

| 5 | Production schedule | We will feedback to the customer about mold processing with weekly

report |

| 6 | Sample shoot | We offer the moulds test samples for confirmation (about 10-15

piece). Then, for customer confirmation. If there are problems, we will modify it

until goods meets your requirements |

| 7 | Package | Wooden case for moulds, cartons for parts ,or as your requiretment |

| 8 | Delivery |

By air or by sea |

9

| After-sales service | Warranty for 12 months |

• ERBIWA Equipment List

| Equipment type | Qty(Set) | Model | Brand |

Origin | Precision(μ) | Date of use (Year) | (x*y*z)mm |

| Milling | 7 | 8SS | Taizheng | Taiwan | 0.01mm | 2014 | 600*320*330 |

| 4 | SHCM-97A | Gentiger | Taiwan | 0.01mm | 2016 | 650*350*360 |

| Grinding | 10 | SGM450 | Shuguang | Taiwan | 0.003mm | 2016 | 400*150*250 |

| 8 | JL-614 | Joen Lih | Taiwan | 0.003mm | 2012 | 400*150*250 |

| Drilling | 3 | Z305*16/1 | ZOJE | China | 1mm | 2016 | z=850 |

| 3 | M3-M16 | Xianwei | China | 1mm | 2016 | z=500 |

| EDM | 5 | cnc-edm-he130 | HSPK | China | 0.01mm | 2016 | 1300*600*400 |

| 8 | cnc-edm-he100 | HSPK | China | 0.01mm | 2016 | 1000*500*400 |

| 6 | Sodick AM30L | Sodick | Japan | 0.005mm | 2014 | 300*200*200 |

| 3 | TOPEDM MP50 | TOPEDM | Taiwan | 0.005mm | 2012 | 400*280*250 |

| 4 | ARD M30 | ARD | Taiwan | 0.005mm | 2012 | 250*200*200 |

Wire Cut | 2 | AQ360LS | Sodick | Japan | 0.005mm | 2010 | 360*250*220 |

| 3 | AQ550LS | Sodick | Japan | 0.005mm | 2010 | 550*350*320 |

| 2 | Charmilles 240 | Charmilles | Switzerland | 0.003mm | 2010 | 250*200*220 |

| 1 | CHMER | CHMER | Taiwan | 0.005mm | 2010 | 1300*600*400 |

| 1 | K7 | K7 | China | 0.01mm | 2010 | 1000*500*400 |

| CNC | 5 | α-d14mia | FANUC | Japan | 0.005mm | 2016 | 500*400*330 |

| 3 | MXV1020 | YCM | Taiwan | 0.005mm | 2016 | 1020*520*540 |

| 1 | MV66A | YCM | Taiwan | 0.005mm | 2016 | 660*520*540 |

| 2 | FV85A | YCM | Taiwan | 0.005mm | 2016 | 850*620*630 |

| 1 | FV125A | YCM | Taiwan | 0.005mm | 2016 | 1270*520*540 |

| 1 | TV146B | YCM | Taiwan | 0.005mm | 2014 | 1400*620*630 |

| 2 | Hartford-2150H | Hartford | Taiwan | 0.01mm | 2014 | 2000*1500*780 |

| 1 | Hartford-1000 | Hartford | Taiwan | 0.01mm | 2014 | 1000*600*630 |

| 2 | TAKUMI H16 | TAKUMI | USA | 0.01mm | 2017 | 1600*1300*700 |

| 1 | MB-56VA | OKUMA | Japan | 0.005mm | 2014 | 1000*560*550 |

| 1 | 5 Axis AV-2516X/2516HX | Quick Jet | Taiwan | 0.004mm | 2017 | 2500*1600*800 |

| 1 | 3 Axis AV-1612 | Quick Jet | Taiwan | 0.002mm | 2017 | 1600*1200*700 |

Inspection

| 2 | Inspector | Hexagon | Sweden | 0.002mm | 2016 | 2000*1000*700 |

| 6 | Microscope | Micat | Taiwan | 0.002mm | 2016 | 400*300*150 |

| 1 | Mitutoyo C7106 | Mitutoyo | Japan | 0.003mm | 2014 | 1500*800*500 |

| 2 | MF-A1720 | Mitutoyo | Japan | 0.003mm | 2014 | 400*300*150 |

| 1 | Micro-Hite M600 | TESA | Switzerland | 0.005mm | 2014 | 0~600mm |

| 1 | GTR-4 LS | OSAKA | Japan | 0.005mm | 2014 | Gear Tester |

| 1 | MFC1001 | NIKON | Japan | 0.003mm | 2015 | Z=100 |

| Injection Mold Machine | 4 | Haitian 100 Ton | Haitian | China | | 2012 | 100T |

| 1 | Haitian 180 Ton | Haitian | China | | 2012 | 180T |

| 1 | Haitian 200 Ton | Haitian | China | | 2012 | 200T |

| 4 | Taichung 120 Ton | Taichung | Taiwan | | 2014 | 130T |

| 1 | Taichung 200 Ton | Taichung | Taiwan | | 2014 | 200T |

| 1 | ARBURG 420C | ARBURG | Germany | | 2016 | 110T |

Feature Of Plastic Injection Mold

- Plastic injection mold

- cover or Lid parts

- PP material

- 1*4 injection mold

- H13 (HRC48-52) Steel

- YUDO Hot runner

- Full hot runner

- Automatically running

- HASCO standard

- Short cycle time

1, Start from part design analysis.

2, Mold design drawing and DFM report available so you can see how

is the mold going to be before mold making.

3, If product is complex, moldflow report will be present as well.

4, In house mold making shop ensure you mold quality under well

control.

5, Normally it takes 20-40 days to make mold, precise time depends

on part design.

Application Of Plastic Injection Mold

- Use for machinery

- Use for electronic

- Use for automotive

- Use for information technology industry

- Use for Space industry

- Use for Medical industry

- Use for Energy industry

• Photos of Air Cleaner Intake Duct

Kindly contact me if any questions. It is our pleasure to be on

service of you.

We sincerely hope to cooperate with customers from home and abroad.

We promise to provide you cost-effective products and superior

services, why not have a try?