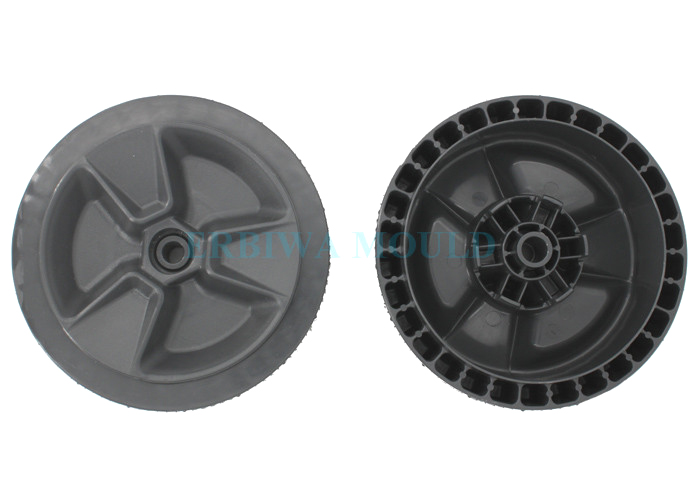

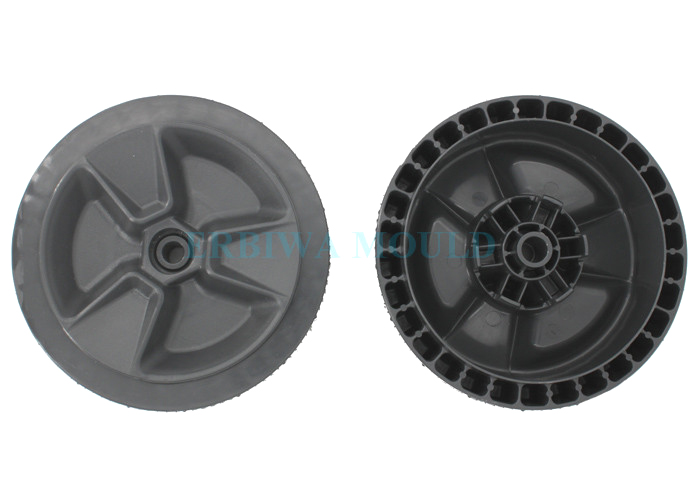

2 Cavities Custom Plastic InjectionTooling For Stable Round Auto

Wheel Boss Parts

♦ Mould Description

| Company | ERBIWA MOULD INDUSTRIAL Co., Ltd |

| Business Type | Manufacturing |

| Products Name | Chinese high quality customized plastic injection molding for Car

Plastic Secondary Instrument Panel/Dashboard |

| Place of Origin | Dongguan, China |

| Export Country | Germany, Japan, North America, Australian, Canada, France, Italy,

etc |

| Quality System | ISO9001: 2015; IATF16949: 2016 |

| Mould Life | 300,000-500,000shots |

| Mould base Standard | HASCO, DME, LKM, FUTABA, etc |

| Core & Cavity Material | Nak80, P20, H718, S136, SKD61, 2738, DC53, H13... |

| Products Material | ABS, PP, PVC, PET, PA66, PA6... |

| Design Software | UG, ProE, Solidwork, AutoCAD, Moldflow... |

| Runner | Hot runner or cold runner |

| Gate | Side gate, Sub gate, Pin point Gate... |

| Surface Treatment | Polish, High gloss Polish, Texture, Silk-screen printing, Brushed,

Mirror, Anodizing, Electroplating, etc |

| Equipment | CNC, EDM, Milling, Grinding, Wire Cut, Inspection, Plastic

injection machine |

| Package | Wooden box for mould, carton for plastic products |

| Lead Time | 35-40days for T1 |

| OEM/ODM Service | Available |

♦ Plastic Moulds Production Process

1. R & D

Customer sends us sample or drawings, we do modification as per

customer asked, Some professional suggestion to help customer

improve the product details, we can provide design service if

needed

2. Negotiation

The options of steel, delivery time, payment item, ect.

3. Place an order

Customer confirms the plastic material, machine spec. special

requirement on details. We start the drawings

4. Mould Design

We make mould design on the basis of confirmed product design,

accordingly customer machine spec. and requests to make mould

design

5. Mould Tooling

We start to make mold after mold design confirmed, Cut steel, CNC

machining, polishing, sampling

6. Mould Processing

mould process photos update to customers each week

7. Sample Shot

T0 - T1: Checking if mould running corrects, the dimension, weight,

wall thickness, if meet customer's request, if all ok, arrange

samples to customer

8. Delivery time

Once sample approved, we will ship the moulds in 7 days after get

customer shipping instructions

9. Shipping

By Sea or By air, Nearest port-Shenzhen, Nearest airport: Shenzhen

or Guangzhou

♦ About Us

We provide not only plastic injection mould, but injection

services. And we are a professional mold maker from China with more

than ten years experience in common mold, metal inserted mold,

bi-material injection mold, hot runner mold, overmold, etc.

Our main product lines are moulds for plastic, metal and rubber

components of automotive plastic parts, household and industrial

electronic devices, plastic toys for children, educational devices

and talking pensd for children and adults, plastic products for

advertisement, medical parts, etc.

To provide our customers best quality and reliability of production

we make strict quality control from the beginning of drawing

conformation until the final packaging. We use safe high-quality

materials and work with experienced factories.

We are an experienced and professional team, we have export our

products to many countries and regions all over the world. Our

products enjoy good popularity among our customers. We welcome

customers, business associations and friends from all parts of the

world to contact us and seek cooperation for mutual benefits.

♦ FAQ:

Q1. When can I get the price?

A: We usually quote within 24 hours after we get your inquiry. Or

please call us or send us email so that we will make the quotation

soonest.

Q2. How long is the lead-time for mold?

A: It all depends on the mold’s size and complexity. Normally, the

lead time is 25-35days. If the molds are very simple and with small

size, we can work out within 15 days.

Q3. I have no 3D drawing, how should I start the new project?

A: You can supply us a sample, and we will help to finish the 3D

drawing design.

Q4. Before shipment, how to make sure the products quality?

A: We will supply you a video for production process detail include

process report, products size,

structure and surface detail, packing detail and so on.

♦ Product Show

RFQ is always welcome, we sincerely hope to cooperate with customer

from home and abroad.

Kindly contact me if any questions. It is our pleasure to be on

service of you.